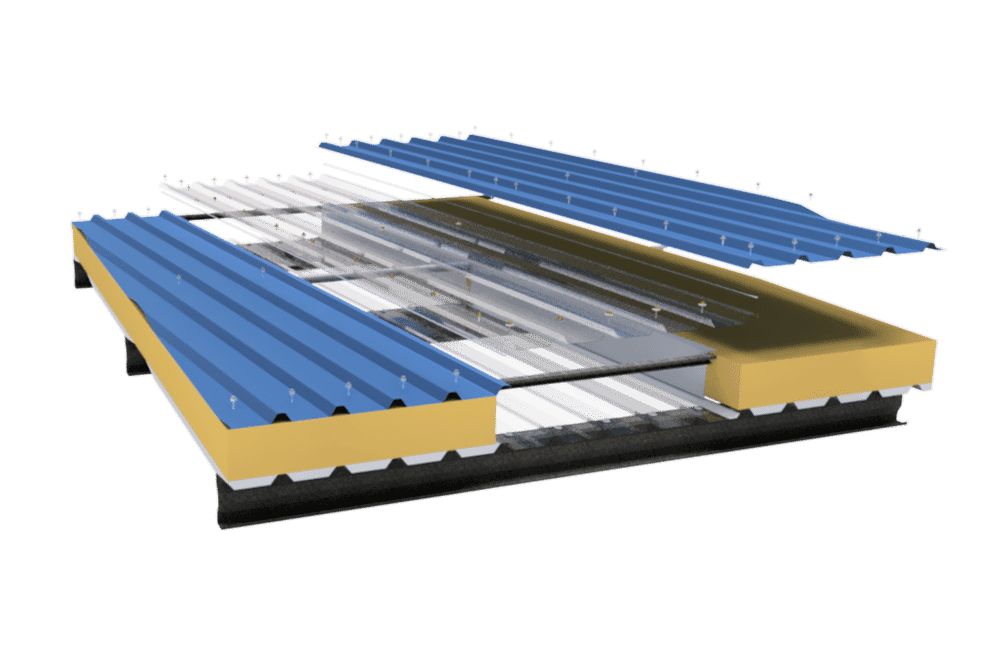

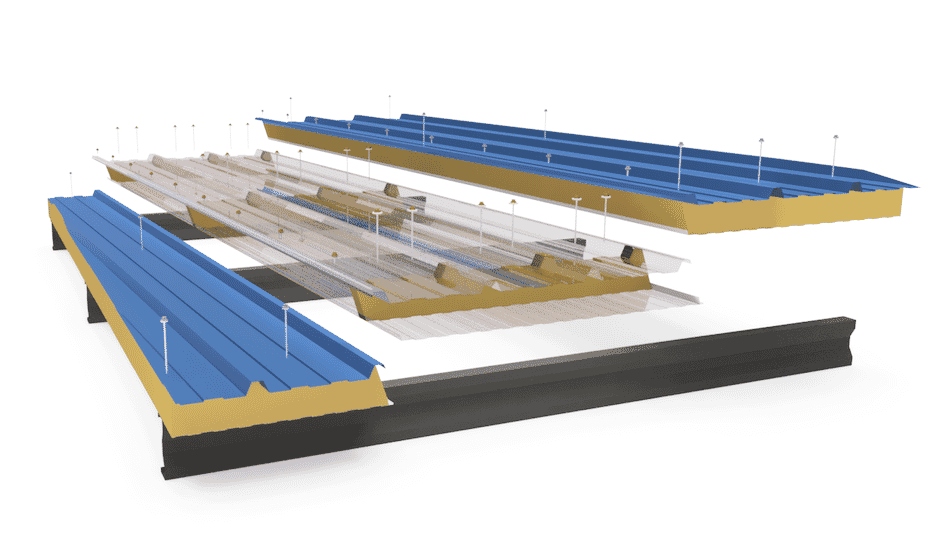

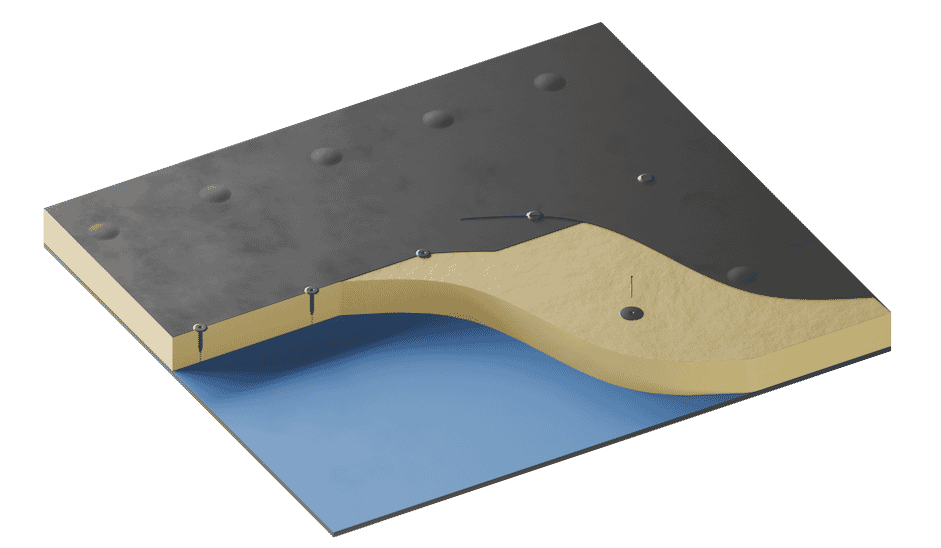

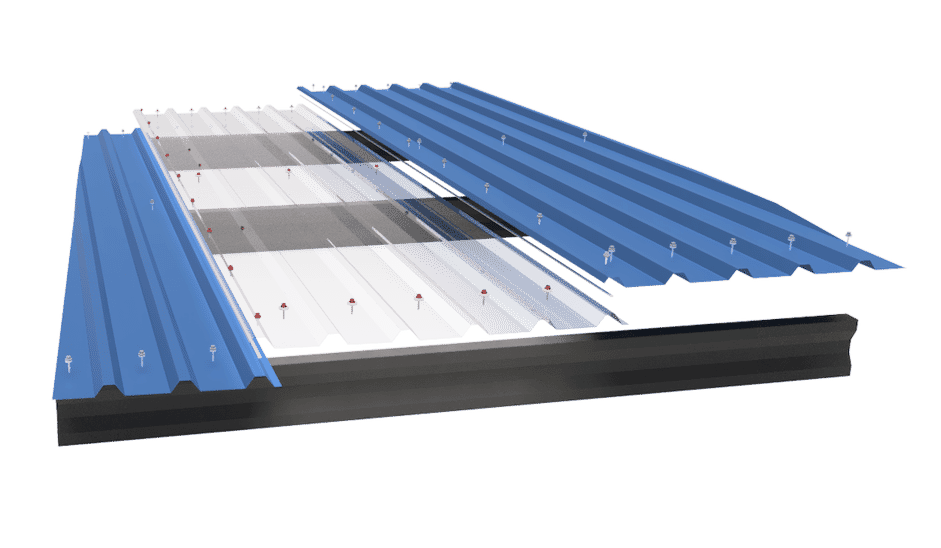

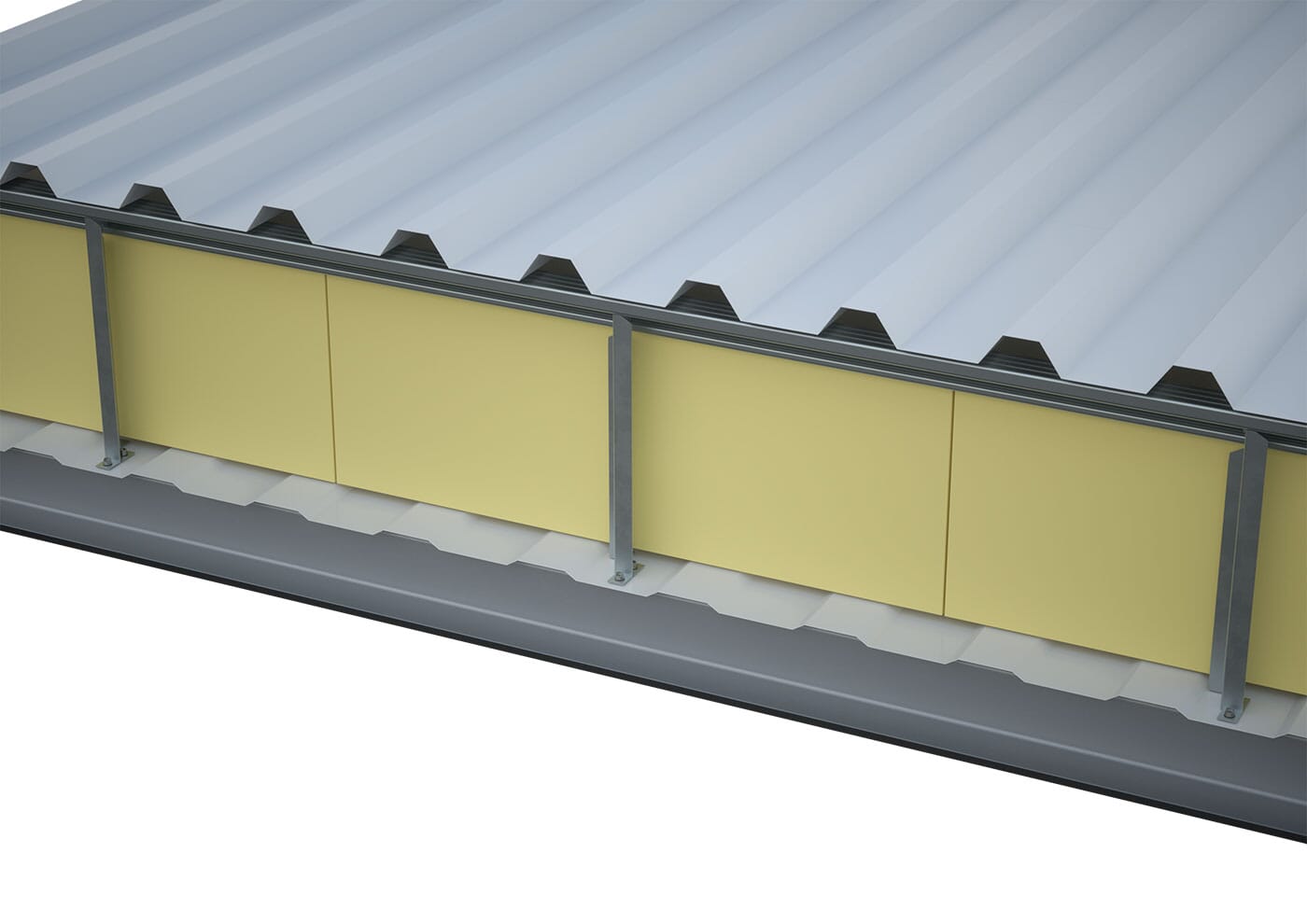

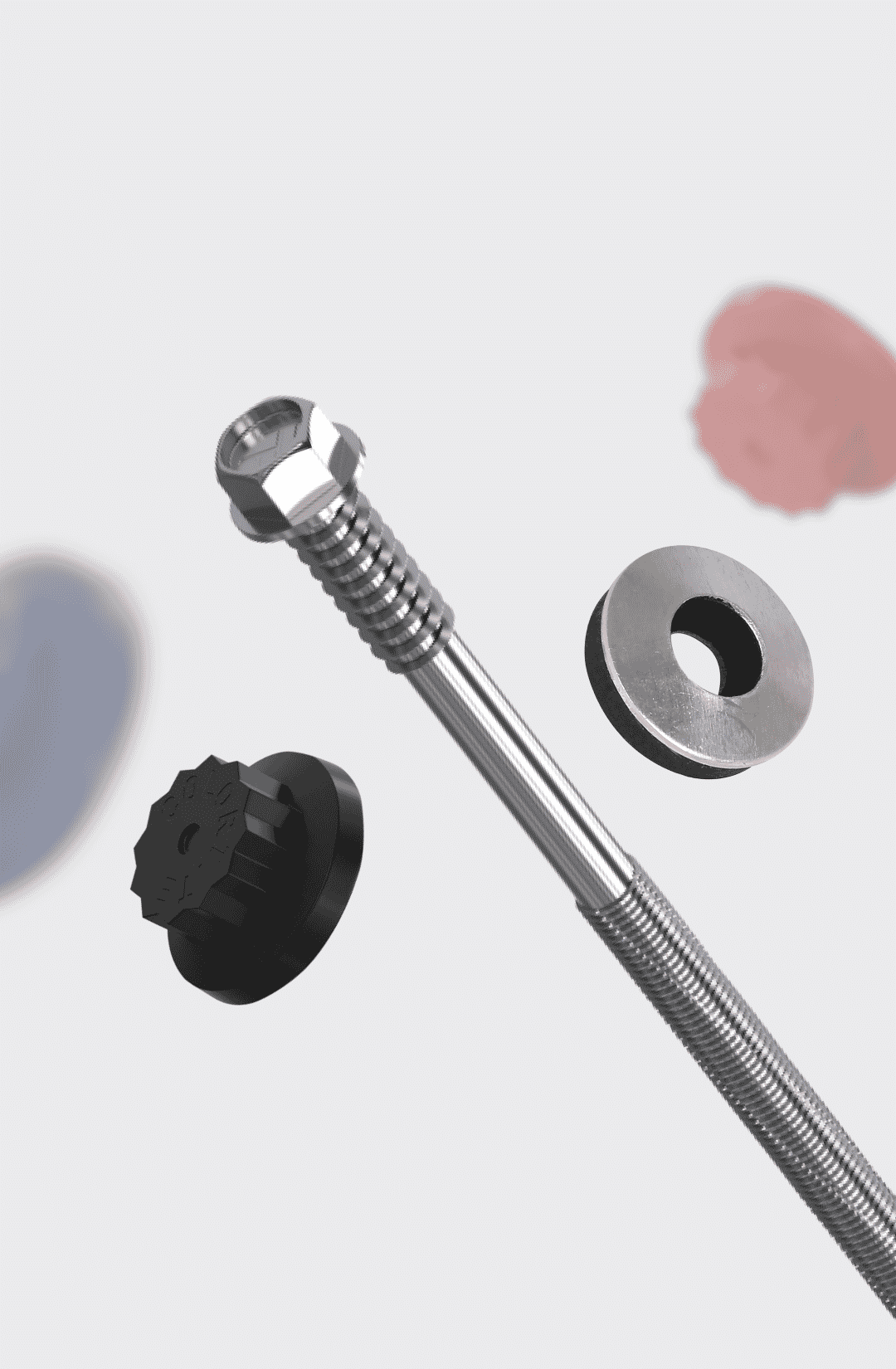

Built-up/Twin Skin Systems

Everything you need for fixing Twin Skin Systems under one roof.

One-Stop Shop

All the fixings and components you need under one roof.

Investment

Investment in advanced machinery and millions of fixings kept in stock.

Customer Service

Access to a dedicated support team you can rely on.

Technical Expertise

Tailored advice to help you select the right products.

A seamless

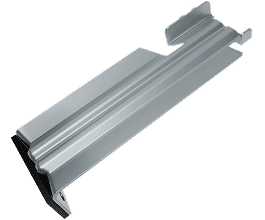

Roof fixings that are innovatively engineered to work together.

Overview – Built-up/Twin Skin Systems

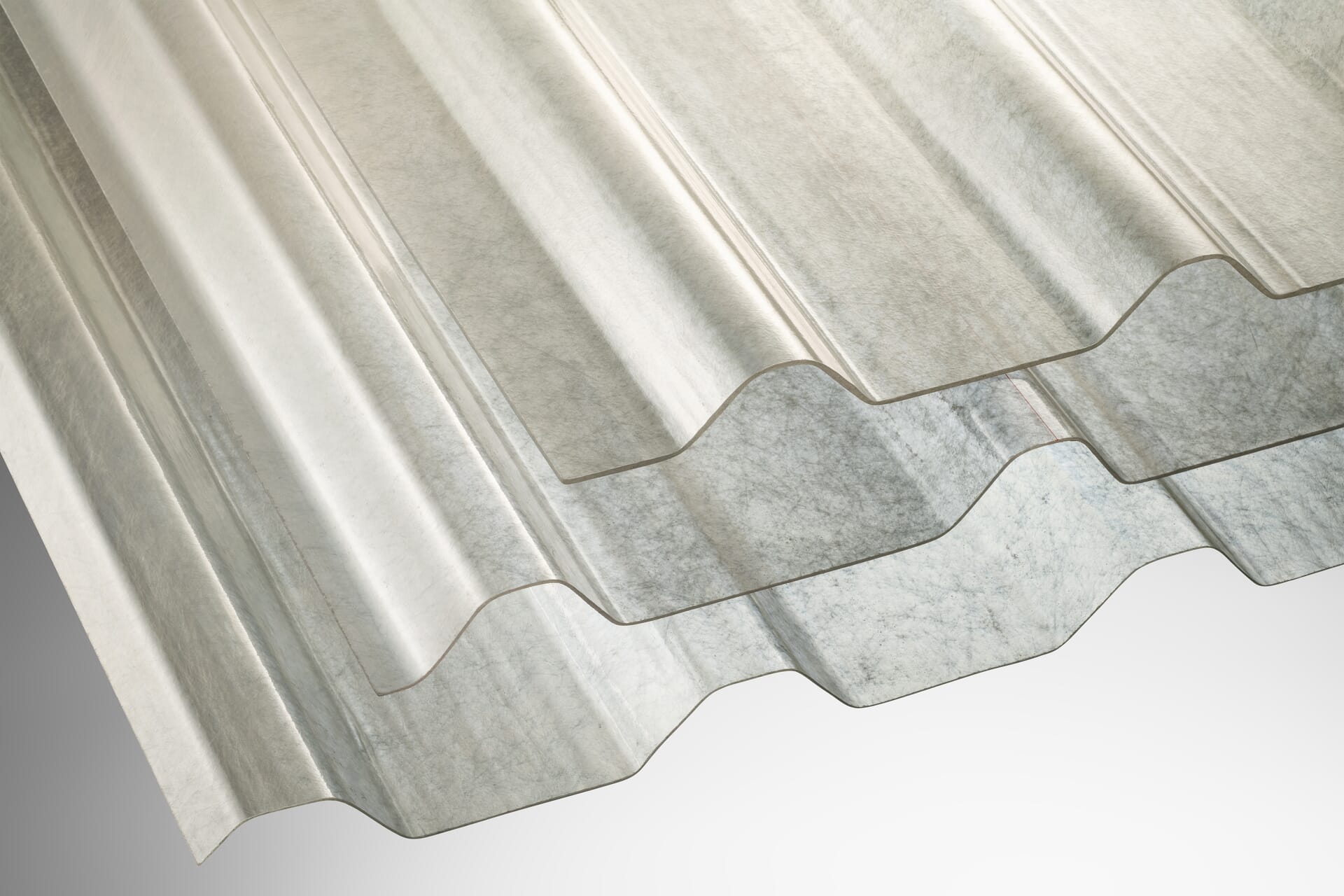

Fixing Point supplies fasteners and components for twin-skin roofing and cladding, serving UK and global clients. With innovation, expertise, and support, we deliver cost-effective solutions that cut waste and simplify site work.

Case studies

See how we raise the

bar in everything we do.